When you press a pulse oximeter against your finger, the tissue deforms. When a surgeon navigates...

Optical Phantoms in the Age of AI Factories

At QUEL Imaging, our mission has always been to accelerate the clinical translation of biomedical optical imaging technologies. Our first market has been fluorescence-guided surgery, where imaging systems take many forms—from hand-held cameras to minimally invasive robotic platforms.

The company was born from a simple realization: the field needed better, more quantitative ways to characterize system performance. This concept had been explored for years in academic settings, and it ultimately culminated in the AAPM TG-311 report, published at the end of 2023. That guidance was the result of nearly a decade of discussion and collaboration among experts worldwide, and it validated much of the early thinking that inspired QUEL’s creation.

From day one, our team has championed the use of quantitative, reproducible metrics as the foundation of progress. That principle has guided our manufacturing, our quality management system, and our approach to every product we make.

And it’s why, in an age defined by AI, our mission feels more relevant than ever.

AI Factories and the Need for Ground Truth

Recently, a few of us from QUEL attended NVIDIA GTC DC 2025. One of the major themes was the rise of AI factories—the idea that value is created by transforming raw data into intelligence. While much of the world first experienced AI through chatbots, the next frontier will be in automation, robotics, and scientific discovery.

But here’s the catch: AI models only learn well when they are trained on reliable data. In other words, they need a source of truth.

That’s where we see QUEL playing an essential role.

Our optical phantoms provide a physical foundation for that truth. Each one is manufactured under a rigorous quality system focused on reproducibility and traceability, ensuring that the data collected from them can be trusted. Data generated with our phantoms can be tokenized and used to train AI models—but the real value of those tokens lies in the integrity of their inputs.

Two Examples of Where This Leads

1. Fluorescence-Guided Surgery

Our reference targets are designed with well-characterized fluorescence and optical properties. When paired with our open-source image-analysis tools, users can extract quantitative metrics that both benchmark system performance and generate high-quality metadata for AI training.

We’ve also validated Monte Carlo models for our phantoms, allowing the same design data used in manufacturing to generate digital twins with assigned material properties. This combination of physical and simulated data multiplies what’s possible—helping researchers predict sensitivity, optimize parameters, and accelerate system development.

2. Optical Health Trackers

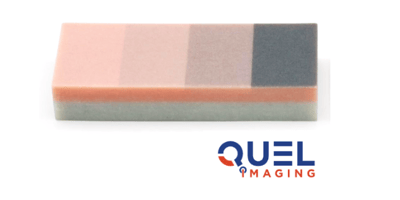

For wearable and skin-based sensing, our OptiBlox® phantoms can model layered tissue with tunable optical properties such as melanin content or chromophore distribution. These physical models serve as reliable calibration standards—but digital extensions can explore far more configurations than can be built by hand.

This hybrid physical-digital approach is now supported by evolving FDA guidance, which explicitly encourages the use of phantoms and computational models in regulatory submissions.

Looking Ahead

We started as a phantom company, but we’re evolving into something broader: a partner that provides both physical standards and digital twins to anchor and accelerate AI-driven innovation in optical imaging.

The phantoms remain our ground truth, while the simulations expand the horizon of what can be tested, modeled, and understood.

It’s an exciting time to be at the intersection of AI, optics, and healthcare, and I couldn’t be prouder of the team at QUEL Imaging for helping build that future.