When you press a pulse oximeter against your finger, the tissue deforms. When a surgeon navigates...

Heterogeneous Optical Tissue Phantoms using Multi-Material Manufacturing

Traditional optical phantoms have limitations. They're homogeneous blocks of material with uniform optical properties throughout. But real tissue? It's anything but uniform. Blood vessels run through muscle. Fat layers sit beneath skin. Each tissue type absorbs and scatters light differently based on its unique composition of chromophores: proteins, lipids, and water.

The gap between homogeneous phantoms and heterogeneous biology has limited how accurately we can develop and validate optical medical devices. Until now.

Multi-material additive manufacturing is changing what's possible with optical tissue phantoms. By precisely controlling material deposition layer by layer, we can now build phantoms that more closely mimic the spatial heterogeneity of biological tissues across multiple wavelengths.

Why Tissue Heterogeneity Matters

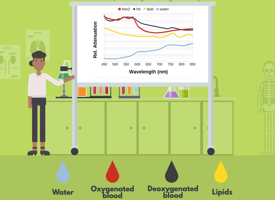

Light interacts with tissue through absorption, scattering, refraction, and transmission. The probability of each interaction depends on tissue composition and the wavelength of light you're using. When tissue is arranged in distinct anatomical layers, capturing the photon transport around and between these layers can critically impact your optical sensing device design.

Traditional homogeneous phantoms can validate basic optical functionality, but they can't replicate the real-world challenges your device will face. They are limited in accurately mimicking multilayer tissues with distinct absorption and scattering properties.

How Multi-material Phantoms Work

Multi-material additive manufacturing builds multispectral optical tissue phantoms by depositing different optical materials in precise spatial arrangements. 3D printing customized formulations finally enables this capability with high colorimetric and optical property accuracy.

Each material in the phantom has controlled absorption and scattering coefficients with materials mimicking blood, lipids, melanin, and other tissue chromophores at specific wavelengths. This provides highly-accurate tissue optical mimicking materials for advanced bench-top testing capabilities in developing all sorts of optical sensing devices.

By combining materials with different optical properties, you can simulate:

Layered tissue structures. Skin over fat over muscle. Each layer with its own chromophore concentrations and scattering properties.

Vascular networks. Embedded channels or regions with blood-mimicking optical properties, complete with spectral differences between oxygenated and deoxygenated hemoglobin.

Anatomically accurate geometries. Custom anthropomorphic phantoms that replicate specific organs or tissue regions with their natural heterogeneity intact.

Controlled biological variability. Want to test your device across different skin tones? Different tissue hydration states? Different oxygen saturation levels? Multi-material phantoms let you control these variables systematically when you know the optical properties to target.

All of our optical materials are characterized using techniques like integrating sphere spectrophotometry, time-of-flight spectroscopy, and spatial frequency domain imaging to ensure your target optical properties match your tissue specifications with high consistency and controlled biological variability.

Looking Forward

The fundamental shift is already here - and we’re leading the way making this technology available to the biomedical optical sensing community. Our OptiBlox Q-X product line brings these capabilities to your development team, backed by decades of tissue optics expertise, analytical rigor, and world-class traceable manufacturing.

Optical medical device development no longer needs to rely on homogeneous approximations of heterogeneous biology. Managing real-world variability with multi-material manufacturing makes biomimetic phantoms a practical reality.

For medtech developers, this means faster prototyping cycles, fewer surprises during biological validation, and more confident device optimization. For patients, it means better-validated devices that work reliably across diverse populations and clinical conditions.

The gap between phantom testing and biological reality hasn't disappeared, but it's narrower than ever. That's progress worth building on.

Need help developing optical phantoms for your device? QUEL Imaging's team of tissue optics experts can help you design, fabricate, and characterize custom phantoms matched to your specific application requirements. Reach out today to discuss your development needs.

Watch our introduction to multi-material phantom technology: Multimaterial Optical Phantoms Video